Although the use of Structural Insulated Panels (SIPs) started more than 85 years ago, SIPs are on the cutting edge of building methods for the 21st century and beyond. Structural Insulated Panels constitute a high-performance building system which can be used for both residential and light commercial construction. The panels consist of rigid foam insulation sandwiched between two sheets of oriented strand board (OSB). SIPs are used to construct the wall and roof assembly, meaning there are no traditional “studs” or trusses making up the shell and structural components of the building.

SIPs can be engineered to fit nearly any building design. The result is a building that is overwhelmingly energy efficient AND strong. Let’s hone in on the key elements of SIP construction and the benefits provided thereof.

SIPs can be engineered to fit nearly any building design. The result is a building that is overwhelmingly energy efficient AND strong. Let’s hone in on the key elements of SIP construction and the benefits provided thereof.

Thermal Performance

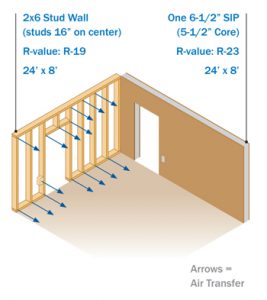

SIP wall and roof systems are constructed by placing and joining together the individual pre-fabricated panels on site. Various R-values can be selected for the panels depending on the building’s climate zone. Although framing members are required to join panels together, and structural headers or columns may be required inside some panels, SIPs offer nearly CONTINUOUS insulation throughout the wall and roof systems, exponentially decreasing the “thermal bridging” that occurs through the framing members of traditional construction methods.

Structural beams are used at roof ridges and bearing points to allow for a continuous plane of roof panels. Another reason for the exceptional thermal performance of SIPs is air-tightness. This is again because there are SO many fewer “joints” in the assembly through which air can infiltrate. In addition, as a standard specification of the SIP construction process, all joints and

connections between panels are sealed. According to the Structural Insulated Panel Association (SIPA), SIPs are known to be about 50% more energy-efficient than traditional “stick” framing. Laboratory testing done by Oak Ridge National Laboratory (ORNL) found that blower door tests revealed that a SIP test room is 15 times more airtight than its stick framed

counterpart with fiberglass insulation.

Structural Performance

Structural insulated panels also have an advantage when it comes to strength. SIPs structural properties are similar to that of a steel W beam. The OSB sheathing on each side of the panel act as the flange of the beam, and the rigid foam core acts as the web. This design allows for an advantage over conventional framing in handling in-plane compressive loads. In fact,

according to SIPA, the load bearing area of SIPs is equivalent to building with 2×10 framing at 16 inches on center (conventional framing is 2×4 or 2×6 at 16 inches on center).

Better Air Quality

We’ve already mentioned the ability for SIP construction to produce an air-tight building envelope. This allows for ultimate![]() control of the indoor environment through calculated outdoor air exchange, humidification/dehumidification, and air distribution without the unwanted infiltration of air and vapor that is more common in code-minimum traditional framing. This also means that the mitigation of mold and mildew growth is much easier in a SIP building.

control of the indoor environment through calculated outdoor air exchange, humidification/dehumidification, and air distribution without the unwanted infiltration of air and vapor that is more common in code-minimum traditional framing. This also means that the mitigation of mold and mildew growth is much easier in a SIP building.

Sustainability

Because SIPs are highly energy-efficient, as we have discussed, it follows that a SIP building will ultimately consume less energy than its counterparts, contributing positively to the environment by reducing CO2 levels. In addition, SIPs produce much less construction waste during installation than traditional framing methods because of the precise engineering and manufacturing process used to minimize waste. Lastly, according to SIPA, significantly less energy is used during the manufacturing process of SIPs as compared to traditional framing methods.

Install Time

During the design phase of a SIP project, a detailed submittal package is produced for panel installation; every panel is labeled and every connection detail is accounted for. This allows for a smooth installation and minimizes the amount of questions that may arise on site. SIP manufacturers and SIPA all claim that this leads to a faster framing installation than conventional methods. In fact, SIPA states that a properly trained SIP installation crew can cut framing time by 55% compared to conventional wood framing. In our experience, this will depend on the overall complexity of the home, site accessibility, and the availability of experienced SIP installers in the local labor market.

Ready for your own custom home with Structural Insulated Panels?

Radiant Homes pursues distinguished design paired with exceptional functionality. We pride ourselves on the ability to utilize advanced building methods and materials, such as SIPs, in order to deliver custom homes that dazzle our clients with eye-catching design as well as exceptional performance. Check out some of our projects here and contact us if you have questions.

Interested in learning more?

Check out this video for a cool visual of how SIPs are used to construct a home.

SIP Video